She feels really easy and comfortable to sail, even in a good breeze and a chop.

- Good looking

- Fast

- Low cost racing yacht

- Great uses of secondhand rig, sails and deck gear

Forty years ago, the splash of amateur-built yachts being launched was a weekly occurrence; these days they’re a rarity. And if we’re talking amateur designed as well as built yachts, well that’s about as common as being struck by lightning.

Enter Allan Roper, the designer and builder of racing yacht Saturday Night Special, named after the Lynyrd Skynyrd song. A life-long yachtie, Roper grew up building and racing Cherubs and skiffs, and now in his fifties, he was keen for something more substantial that still got up and boogied.

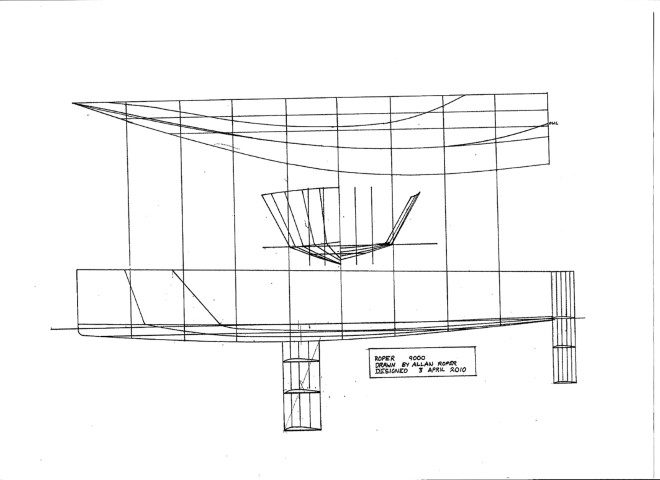

Design

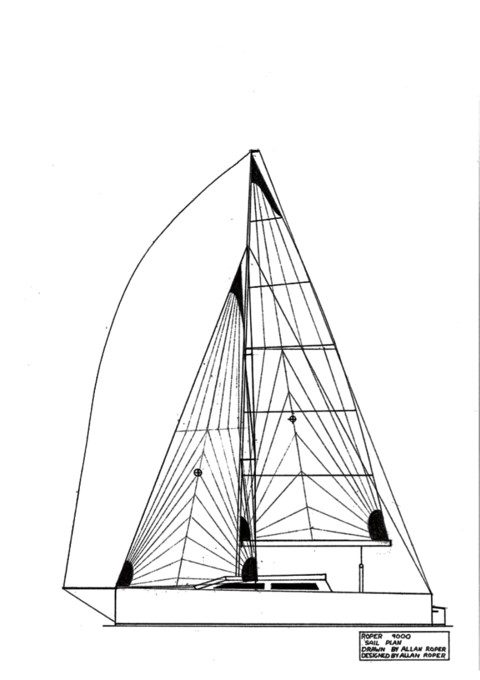

Some years ago, Roper scored a Ross 930 mast, rigging and mainsail, and while he would have preferred something around 12m long, pragmatically Saturday Night Special was designed around this rig.

This meant beginning with a calculator rather than a pencil, the rig’s size determining the yacht’s length, beam and displacement. Furthermore, Roper’s careful study of Bruce Farr, John Spencer, Des Townson and Murray Ross designs showed fast boats used a 5:1 ratio between waterline length and beam.

Another design parameter was the width of Roper’s shed, which limited overall beam to three metres maximum. These numbers provided Roper with a self-imposed box rule in which to draw the fastest, lightest hull possible.

Construction

Having grown up with Spencer and Townson designs, Roper had no hesitation opting for plywood construction – it’s light, easy to build, and when sheathed with epoxy, relatively long lasting. It’s also better than most materials from an environmental perspective, because at the end of the plywood yacht’s life it’s much easier to dispose of than, for example, one built from GRP.

Roper based Saturday Night Special’s construction on Spencer’s well-proven stringer-on-frames system.

The hull has nine yellow cedar frames at one-metre centres, supporting yellow cedar stringers on 200mm centres. The Meranti plywood hull skin is mostly single-skin nine-millimetre, with 6:1 scarf-joins backed up with butt-blocks. However, the lower forward sections are diagonally planked in two skins of six-millimetre Meranti.

The remainder of the boat is also Meranti plywood, the rounded turtle deck is two laminations – one of six, the other of four – while the cockpit and side decks are single-skin nine-millimetre. The whole boat is sheathed in 600-gram DB glass and epoxy.

As Roper intended to keep Saturday Night Special on the poles at Sandspit, shallow draft was a necessity, so he designed a vertical lifting keel. The lift-keel’s case – which is plywood, sheathed internally with 600-gram DB glass and epoxy – extends upwards from the keelson to the deckhead. The keel came from a Mini Transat 650 that never made it to the water and is laminated from vertical-grained mahogany, with a central 25mm steel bolt holding the lead bulb to the bottom.

The keel is lifted and lowered by a trailer winch mounted on a detachable steel frame. It fits over the keel slot through the deck. The keel’s either up or down, locked in each position with a timber wedge and a steel pin. Once locked, the steel frame is removed and stored below.

Roper used Trans O Marine two-pack paints, applied with a roller and tipped off with a brush, for a ‘five-metre finish’ – i.e. it looks great from five metres away or more. Obtaining a 500mm finish, i.e. looking great from 500mm away, would easily double or treble the finishing and fairing work, plus require spraying.

Not wanting the complexity and weight of an inboard engine, Roper opted for a stern mounted outboard, perfectly adequate for the yacht’s intended use.

During his years working as a sales representative for Harken Foster’s, Roper managed to acquire nearly all of Saturday Night Special’s rigging components from upgrading owners, which helped keep his costs down.

The project has taken Roper three years of nights and weekends. However, he did build most of the hull during a full-time, six-week stint, which gave the project a good

shove along. While he didn’t track his hours, the financial cost came to less than $30,000 – an excellent effort these days when people are spending that amount on a paint job or a set of sails.

Sailing

As arranged, we met up with Roper, his son Tim and his other crew aboard Saturday Night Special inside Kawau Bay. The weather was excellent for our purposes – a puffy SW ranging from 8 to 18 knots and a nice chop to add some photography interest.

Apparently, our outing was only the sixth time Roper and his crew had sailed Saturday Night Special, so they’re still on a fairly steep learning curve. Despite this, they’ve already managed several podium finishes in races with the Sandspit Yacht Club.Straight up, Saturday Night Special’s a quick little boat. The GPS on Boating New Zealand’s Haines Hunter 660 showed upwind speeds better than seven knots, with over 10 knots achieved downwind under spinnaker.

After roaring around the yacht taking photographs – a bumpy exercise – it was time to get aboard Saturday Night Special for some first-hand impressions. Given the chop and the distinct possibility of ending up in the drink, I opted to leave my DSLR camera safely aboard the Haines Hunter, hence the lack of interior and on-board photos.

Helming Saturday Night Special proved very rewarding and lots of fun – she sails like a big dinghy. As can be seen from the photos, most of the sail area’s in the mainsail and I soon learned the main needs aggressive trimming to keep the yacht on her feet in puffs. However the wide main traveller makes this fairly easy.

To maximise crew weight to windward, Roper’s crew trim the jib sheet on the windward winch, with the leeward winch acting as a de facto turning block. The winches, like most of the other deck gear, are Harken.

There’re plenty of strings to pull, but the layout works really well and Roper’s experience showed throughout. The blocks and other fittings are all minimum size, but nothing’s broken yet, so they’re obviously all too heavy, right?

Saturday Night Special has a relatively narrow waterline beam, and while she heels easily in the gusts, once the chine and topsides immerse she stiffens considerably. However it was noticeable that she’s quicker when kept to more modest heel angles, which comes down to the trimmer and helmsman working as a team.

The helm was slightly firmer than I’d expected, but Roper mentioned he’d raised the blade 200mm to give it bit more bite. Apparently, with the rudder blade fully down, the helm lightens. Even with the blade up, Saturday Night Special went exactly where she was pointed and balanced well.

In best amateur-built tradition there’s still a few things left to do, most pressingly footrests to stop the mainsail trimmer and helmsperson sliding to leeward in the gusts. While a standard spinnaker pole was used during our test, this will be replaced with a sliding prod. The female housing for the prod has already been glassed into the hull below the forestay fitting and it’s angled upwards so the prod end-fitting will finish at deck level.

The other minor change will be the removal of the alloy half-moon from the leech of the ex-Ross 930 self-tacking jib, which was a danger to human health and boat paint when tacking.

A Ross 930 rig is hardly renowned as having the most robust section, but there’s plenty of wires holding it up on Saturday Night Special: forestay, six shrouds, topmast backstay, running backstays and check-stays at the gooseneck. That’s 14 wires to adjust, which should keep Roper busy tweaking for a while.

Interior

Saturday Night Special’s interior is fairly basic, but it contains all you’d need for a weekend away. The daggerboard case dominates the interior visually and, no question, a fixed keel version would be more habitable, especially if combined with the cabin that Roper originally drew.

From the companionway to port there’s a two-burner Origo meths cooker and a sink, with the starboard side left free for access forward. Two plastic tanks reside beneath the sink, one for freshwater and the other for waste, which combined with the chemical WC means no skin fittings. Great idea.

While Saturday Night Special can sleep a race crew of five at a pinch – twin settee berths, twin quarter-berths and a very snug double up forward – two or three would be far more realistic.

Due to the relatively narrow waterline beam, the bunks are set fairly high in the hull for width. The only downside of this arrangement is that, while there’s comfortable sitting headroom under the blister deck when sitting upright, headroom is compromised if you lean back against the hull.

One of the more interesting features is the angled-V main bulkhead. The apex of the V forms the mast compression post as well as the forward support for the lifting keel case, while the outboard edges of the bulkhead are angled far enough aft to bolt the chainplates to. That’s smart idea.

Conclusion

Saturday Night Special is a neat boat: fast, simple and good-looking. Ironically, keeping things simple can be one of the hardest things to achieve, but Roper’s done an excellent job, especially considering his modest budget. It’s more proof a clear vision, an ability to work the numbers, good design and build skills and the discipline to keep things simple can produce a really cool yacht.

And should anyone be interested Roper would love to design a 12m version/>

She feels really easy and comfortable to sail, even in a good breeze and a chop.

At first glance the boat appears to be a large centre console, although hidden beneath the console and forward area is a sizeable overnight cabin.

With classic styling, good performance and class-leading ride and handling, there’s a lot to like about the Caribbean 32.

Solar panels on the vast roof help keep the batteries charged.