‘Behemoth’ is a word which springs to mind or, perhaps more nautically, ‘leviathan’.

- Excellent cruising performance

- Race v ersion available

- Impressive build quality and go-fast looks

Performance catamarans like this carbon 62-footer simply eat up those tradewind miles, while their shallow draught is ideal for gunk-holing.

Most production cruising catamarans have limitations such as upwind ability and are often compromised by their weight. So, for those with deeper pockets and more distant horizons, performance cruisers is the go-to category.

This was the realisation that Kinetic Catamarans company owner Bob Hayward came to in 2015 when he was shopping for one. The dual-national New Zealander-American has spent the last 30 years based in the US – and it’s given him good insight into this market.

Unable to find his perfect boat he partnered with experienced South African multihull boatbuilder Leon Scheepers to take over the former Phil Harvey yard in South Africa, including some of the staff who had previously made Gunboats. They renamed the new company Kinetic Catamarans.

This enabled fast-tracking the new marque after the appointment of Dutch design team Simonis Voogd. The result is a lightweight vessel available in two versions – a performance cruiser and a racer. Our review boat came with twin centreboards but daggerboards are an option.

The first boat splashed at the Annapolis 2019 show, but I caught up with the Kinetic team at the Miami 2020 boat show. The KC62 performance cruiser (hull #1) is the initial model and will be followed later this year by the KC54.

“I was looking to buy a fast cruiser, a Gunboat in fact, but they were winding-down back then so I decided to build my own,” Hayward told me. “Building to the standard of leading premium-market offerings required exacting details. This produces a quality boat that’s also a fast cruiser, ideal for those long Pacific legs for visits to my home in New Zealand.”

Kinetic is a semi-custom yard, building a maximum of three hulls at any one time. “The Kinetic brand is new but our shipyard has a huge amount of expertise with its origins as Harvey Yachts, founded by Phil Harvey, who built the iconic early Gunboat models Tribe and Safari.”

First impressions

The aesthetics of curved bows with fine entries and chined topsides, dominated by a glass-encased saloon, create a striking profile. This go-fast look is backed-up by a performance sail plan, prompting me to declare it ‘best in the Miami Boat Show’. It proved to be a real show-stopper with even the great Vincent Lauriot Prevost from VPLP admiring it.

Of course style without substance doesn’t do too much in the ocean, so my day at sea would reveal all. For boats like these the challenge is blending the raw power with a sail-able package that won’t scare the living daylights out of raw owners and their families.

For large vessels this is where smart technology plays a part. Kinetic recognised this by using hydraulic sheeting, digital systems and even a drop-down thruster. Steering is from three points, with twin tillers outside and a main console wheel at the forward saloon bulkhead. All sail controls are in the foredeck cockpit.

Glass saloon

The carbon structure, including carbon compression posts under the coachroof mainsheet track, allows the saloon to be dominated by windows, creating an airy space. This is enhanced by skylights, including a large one offering the helmsman a view of the mainsail.

Vertical angles and gently sloping, forward-facing windows maximise shade without compromising the great views. Inside, the build is carbon composite furniture with wood inserts including carbon/porcelain worktops with foam core and stainless latches on all lockers and drawers.

All storage is near floor level, creating a clean overall design. The extensive galley is on starboard at the back with the nav station up front beside the steering console; while on port is the lounge-diner area. The result is extensive floor space, yet with enough grab rails, as I found out during a bumpy ride from Miami when the swells broke over the bows and across the flat decks.

The U-shaped galley’s surrounded by generous workspace with storage below – but without fiddles, which I’d have preferred. Equipment includes three Vitrifrigo drawer fridge/freezers and a Miele electric four-burner hob and oven.

There’s double sinks and two watermakers. Renewable power is via 2,200-watt solar panels on the coachroof and there’s also a 6kVa Fischer Panda generator (24V), should the optional washing machine be installed.

Forward helm

All sail controls and halyards are centralised in the forward cockpit. Just one step behind is the primary helm station, inside the front of the saloon, where there’s an array of push-button controls for the sails. These include a dump buttons for the hydraulic mainsheet and the traveller, which is on a line driver.

A good safety option is the Upside Up System from Ocean Data Systems which has quick releases for the mainsheet, traveller and forward sails (if pre-set parameters in shroud tension, pitch and heel are exceeded). Ideally, I’d prefer the button for the latter painted in red, given the KC62’s potential.

Of course this push-button system may lack ‘feel’ but it does give instant control of the sail plan. The moulded console is dominated by two large B&G screens showing trim angles and data. Twin B&G autopilots are the other essentials here for effortless cruising.

Interestingly, there’s no engine throttles; instead, they’re located nearby on the edge of the moulded navigation station with thruster joystick alongside. Handily, there’s also a Dockmate remote handset to control the drop-down bow thruster as well as the Yanmars. Plus there’s a joystick.

All house systems are controlled by the Kiwi-built CZone digital switching bus which gives quick error checking and data feedback to the skipper. Also here is one of the main systems cabinets, neatly fitted by Cay Electronics whose engineer Zack Volpe talked me through this extensive installation.

“Installation is just part of our service because we have to extensively test and support the customer afterwards,” he says. The other main system centre, in a cupboard in the starboard hull, houses inverters and other electronics high up, well above any water incursion.

Owner’s layout

This boat is the owner’s version with a port-side suite and two guest cabins in the starboard hull; accessed via stairs on each side of the saloon. Again, the clean design philosophy delivers a fuss-free finish throughout with wipe-down, faired surfaces.

Viewing the owner’s suite also allowed me to see the extensive structure of the hulls, which have wide longitudinal carbon stringers and ribs for stiffness. The owner’s layout has the athwartships bed midships with bathroom forward and the lounge-study aft.

Good points throughout this suite include generous storage space below the elevated queen-sized bed and a number of portlights which give through-flow of air; ideal for tropical sailing. The other essential in all large sailing cats is also present: an escape hatch on the inside of each hull.

Moving to the starboard hull, the forward cabin has the same layout as the owner’s bed, with the aft ensuite cabin having a fore-and-aft located bed. Below this bed is an engine access point, so not an ideal place of rest when motoring.

Custom rig

Kinetic offers a fixed or rotating mast and a custom rigging plan. Our review boat had the standard package of a Southern Spars high modulus carbon mast with North Sails – ideal for a performance cruiser, as the sailmaker’s Mike Wolfs explained to me as we toured the rig.

“I’ve been working with Bob since the inception of the project and for this boat we recommended 3DI Endurance sails for durability, strength and the kind of tropical climate this boat will spend its time in.”

The sails are a bit heavier than the 3DI raw product, says Wolfs, due to taped seams and anti-chaff protection. The mainsail is manageable, reflecting the original remit of this boat as a short-handed couple’s cruiser (spiced-up with some regatta sailing), so the three slab reefs can be tucked-in quickly from the mast base.

To this end, there’s also a self-tacking jib and track, inside what is a fairly large fore-triangle, extended by the use of the structural longeron spine. This supports a cutter rig with fractional top-down furled genoa/J Zero and the spinnakers.

For upwind, the largest genoa/J Zero is 120% with sheets near the shrouds. The coachroof mainsheet is hydraulic and its traveller is controlled by an Antal line driver (the same type used for the centreboards) reinforced with carbon posts underneath to cope with the loads.

Entertainment aft

The aft cockpit’s fully geared to entertainment, apart from the secondary outboard helm. Tillers give direct control to the quality Jefa quadrant and linkages – you can feel the loads on the twin rudders more acutely, while also having a great view along the race-line of the KC62. Twin wheels are an option.

Views right across the hulls are enhanced by those large windows, plus the two doors at the forward cockpit which blast airflow through when required. The cockpit layout is very clean and simple with couches on each side and across the transom, where you’ll find a BBQ and wet bar.

The entire area is shaded by the coachroof extension and teak underfoot finishes it off nicely. Moving forward is easy along the flat side-decks with their low-profile hatches. At the bows, the forward cockpit dominates, but there’s enough space for lockers, including one for the sizeable windlass is operated within the safe confines of the forward cockpit.

Carbon-infused hull

The main structures of the hulls, bridgedeck, window surrounds and coachroof come from moulds but the rest is custom-built. “The forward and aft cockpits can be changed to suit client requests,” says Scheepers. The laminate is 100% carbon fibre infused with epoxy resin, including all webs, floors and structural shelves.

Hull form has a chine (for more volume in the cabins) and the nacelle has a good, one-metre clearance. Interestingly, the nacelle underside is flat, which may induce wave slap. Designer Maarten Voogd provided his rationale: “We try to maximise bridgedeck clearance to minimise slamming. If we shaped the bridgedeck to deflect waves, it would come lower and therefore have more hits. Our theory is that you want to have no hits at all instead of deflecting the waves. The experience we have with lots of ocean miles on the Leopard Cats made us decide to keep it flat.”

Foils can be centreboards or the more race-orientated daggerboads that enhance lift (they generate two tons on the race-version KC62) and pointing. But for cruising, centreboards are an ideal compromise and the Kinetic ones are mechanically fused to

retract on impact (as they are buoyant). The slight downside of centreboards is additional turbulence in the empty slot when deployed, but for cruising they would be my personal choice.

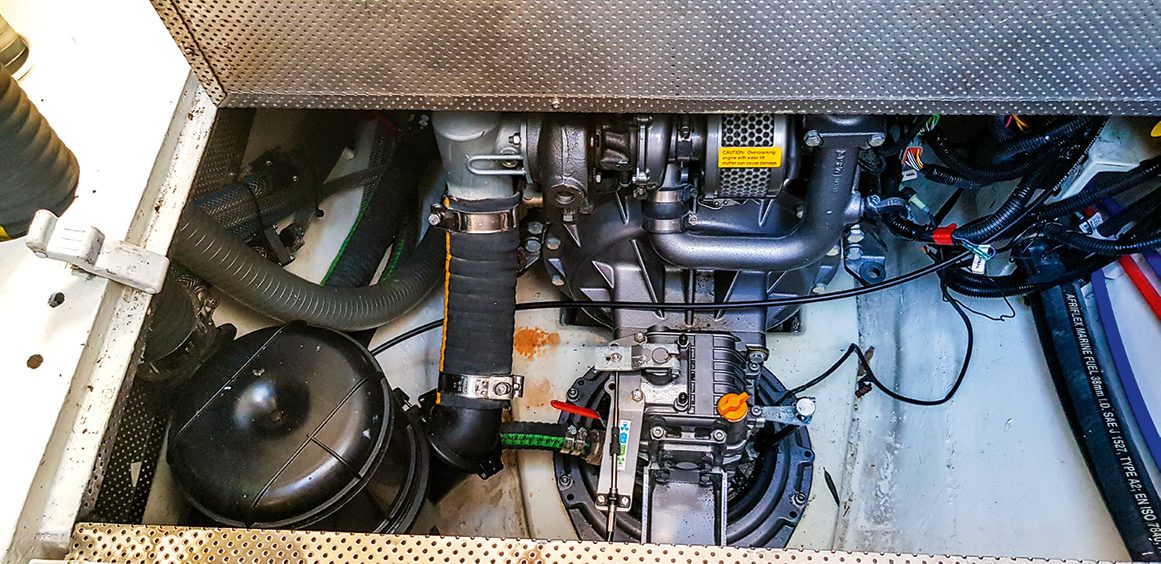

Engine access is via hatches in the aft deck where the four-cylinder saildrive Yanmars have ample working space around them, including the 6kVA Fischer Panda generator on the port side. This boat also has twin Spectra watermakers (one is standard). Tankage is generous (1,400 litres each of fuel and water) and they’re custom carbon builds to maximise volume.

Miami offshore

The striking offshore isthmus of Miami Beach was the ideal setting for sailing the KC62, given its myriad shallows. At the helm, watching the B&G plotter, I stood between it and navigation station to operate the throttles for the engines as we headed south.

The GPS showed a 9.8-knot cruising speed (2,100rpm at 9lph), aided by the overdrive pitch change on the Gori propeller, before we slowed to hoist the sails. All halyards were nearby at the mast base and the big electric Harkens quickly hoisted the mainsail, guided by lazy jacks.

In the forward cockpit, we were protected from the swells that broke through the trampolines, and large scuppers removed the water. Turning off the wind we unwound the genoa and began sailing. At the carbon helm, I steered with two hands to cope with the pressure, until I called for some trimming which eased the load on the spade rudders.

The sailing numbers matched our power figures, with 9.5 knots boatspeed at 50° apparent in the 15-knot breeze. At the push of a button I hardened up the sail plan to improve our pointing to 29°, and a boat speed of 11 knots.

This while bashing into 2.0m lumpy seas – a tough test but nothing in the KC62 groaned or complained. Tacking was quick and easy: both keels were fully deployed by push button, before I put the helm down and the spade rudders pushed the KC62 easily onto the new tack.

Expedient cruising sailors would have gone off the wind and hoisted the Code 0, so we did likewise, unfurling and sheeting it beside the aft bulwark of the coachroof. With speeds touching 12 knots and smoother sailing, the Florida Keys beckoned – a stunning cruising ground for a stunning performance cruiser.

/>

‘Behemoth’ is a word which springs to mind or, perhaps more nautically, ‘leviathan’.

White Pointer has earned the respect of discerning customers in New Zealand and Australia, attracting a loyal and ever growing following for its high-quality, rugged and totally dependable aluminium trailer boats.

The hardtop SP635 shares the same underpinnings as the popular SF 635 which was a completely new model back in 2020.

The pride and joy of a multi-generational family, Bliss resides on a pier that’s home to a couple of other Elite motor launches – Sandspit Marina is a hot-spot for the Bill Upfold-designed vessels, with several calling this small marina home.