Monster iceberg threatens South Georgia

A massive iceberg which broke off Antarctica’s Larsen C ice shelf in 2017 is now drifting northeast towards the island of South Georgia, a…

Gulf Harbour named best marina

Auckland’s Gulf Harbour Marina has been crowned the Marina of the Year at this year’s awards ceremony organised by the New Zealand Marina…

More Kiwis boating

New Maritime NZ research highlights the changing face of recreational boating in New Zealand, with 1.7 million adults now out on the water…

Wee dram for Naiad?

Picton-based naval architecture company Naiad has joined The Whiskey Project Group – an Australian watercraft design and manufacturing…

Samantha is match racing champ

Samantha Norman and her crew of Bex Costello, Hana Hielkema, Polly Powrie and Miranda Addy have been crowned 2020 NZ Women’s Match Racing…

Solo rower sets record

After three months alone at sea, 40-year-old Brit Lia Ditton has set a new women’s world record for rowing solo from San Francisco to…

Navy recruits in Classic

This year marks the 22nd time the Navy’s three 40-foot training sloops will be tackling October’s iconic PIC Coastal Classic.

Patriotic paint job

A luxury mini-expedition yacht in Tauranga is looking resplendent in her new livery, courtesy of a range of specialist marine coatings…

Kennedy Point marina on target

Contractors are scheduled to begin work on the Kennedy Point Marina on Waiheke Island in September.

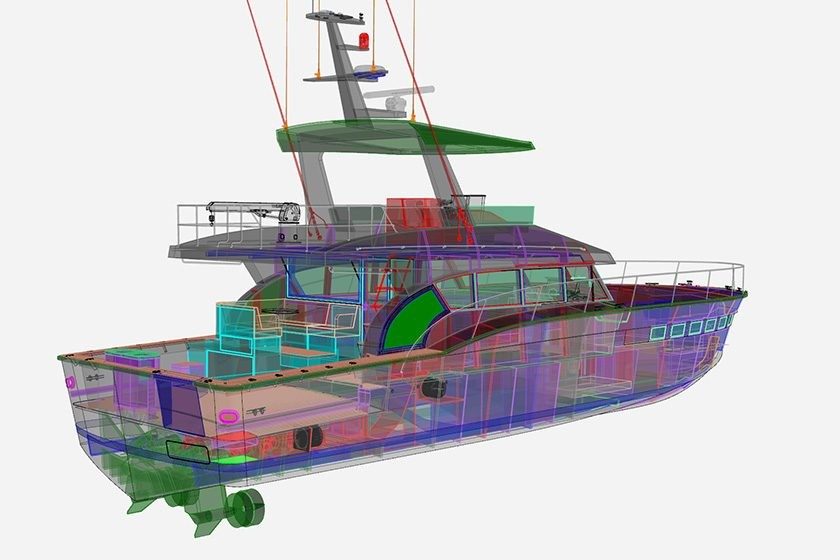

Maritimo’s best yet?

In June Australian luxury motor yacht builder Maritimo side-stepped Covid-19 restrictions by staging a ‘virtual launch’ of a new model soon…

BUILDING WITH PRIDE

Auckland’s Lloyd Stevenson Boatbuilders will soon begin building its latest custom project – an 18m high-speed, full-carbon sport-fisher –…

88s ramp up safe sailing

After six weeks on pause it is time to press play. The Young 88 Association has worked with the organising authorities to make a diverse 88…