IT’S EASY BEING GREEN

Modern engineering makes it easy to reduce boating’s environmental impact while saving money at the same time.

Yesterday’s Charm

When Mason Clippers were advertised in Sea Spray magazine in the ‘60s the byline read: “The world’s finest powerboat – for those people in…

The beauty of junk

There are books and then there are dangerous books. Dangerous books cannot be forgotten and can change your life. Sailor/author Annie Hill…

TRUMPY ICON FOR SALE

Launched in 1947, an elegant motor launch designed and built by one of America’s best-loved naval architects is on the market after a…

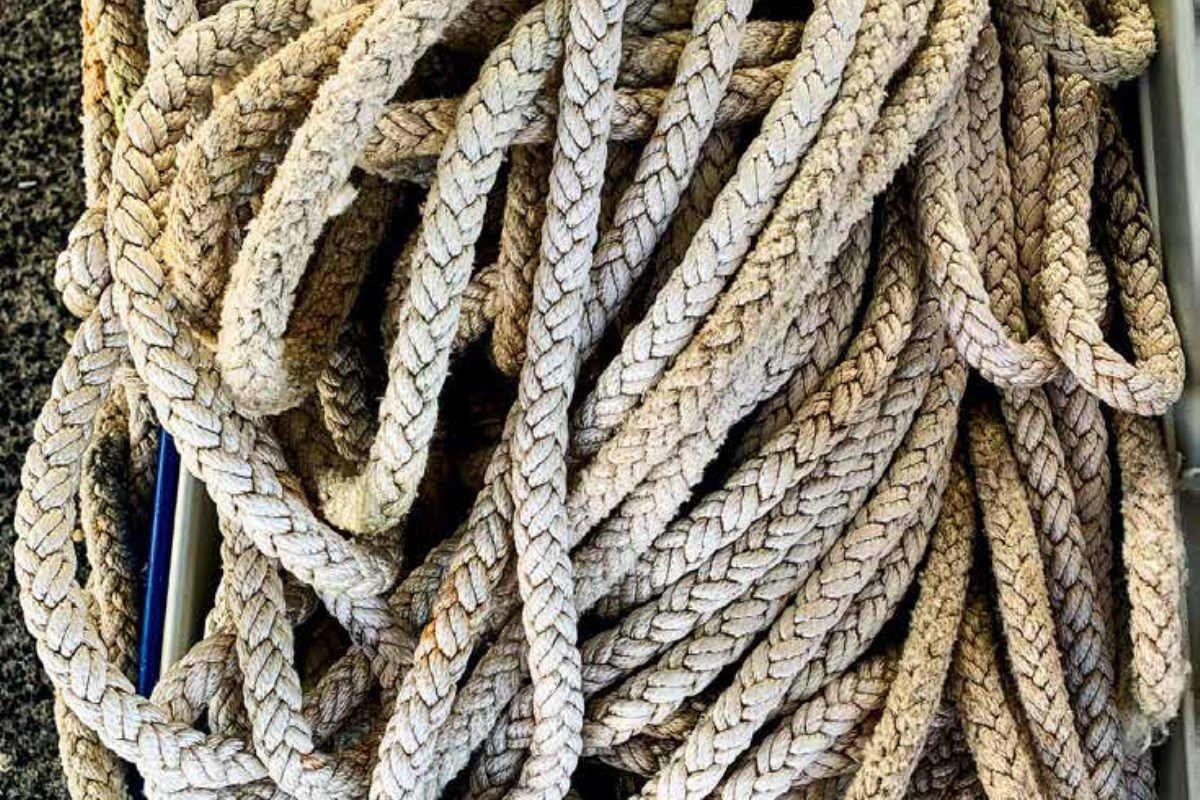

Caring for your anchor rode

When did you last wash your anchor warp? Not a common maintenance item, but something that may be worth considering, especially if your…

Bracing for winter

I always feel a little sad when the last vestiges of summer disappear and winter can no longer be denied.