Procrastination is the thief of time, says the old adage, but as any boatie will tell you, procrastination is also the death of the bank balance – if you have to save the boat. Actor Peter Elliott undertakes a lockdown project.

In no way can I claim to be a boatbuilder. I’ve dabbled in the shallow waters of a sheltered pond at best, but I did start a project some years back that turned me into an interested party at least.

Since boyhood I’d wanted a canoe – a proper birchbark, American Indian-styled paddler’s canoe. When I was a young lad, my dad found me a small, plywood, boxy-style boat that withstood many subsequent adventures, but was never the design of my dreams, and it fell to bits from neglect some years later.

Torea – as it was called – started my love of boating and it did me valiant service, even as I betrayed its stout little heart by spending little time servicing its needs.

In boyhood manner Torea was just a means to an end: river explorations, harbour tours and estuary fishing. Dad spent time getting it ready for his youngest’s birthday. Tiny and misshapen though it was, I recognised the importance of what he had done for me. Perhaps that fuelled my later guilt about its neglect.

Fast-forward 25 years, and I am working on a nightly soap opera as head of the clinic at Shortland Street – David Kearney. I was finding line-learning tiring and factory-like. I was three years in, without a break, and I needed something to take my mind off the process.

I needed to do something that had a journey – a beginning, a middle and an end. And I wanted to see something tangible from efforts, not just fleeting moments of tele, barely glimpsed as New Zealand ate its nightly dinner.

Mike Becroft, a friend who had built canoes, showed me his and it rekindled my desire from all those years before. I fell in love with its lines and curves, the smooth warmth of wood and craftsmanship.

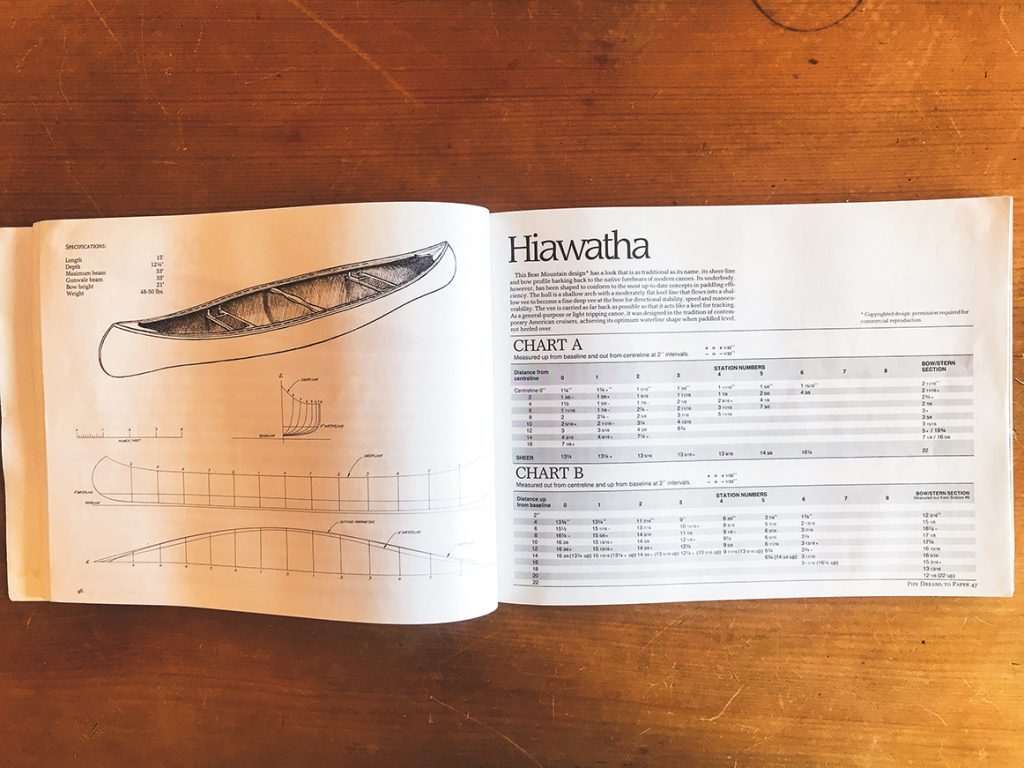

Mike helped me find a supply of bead-and-cove-edged ¾-inch strips of cedar and shortly thereafter a bunch of splintery sticks arrived. Now what? I sent off to Bear Mountain Boats, Canada, for the plans. A week later UPS delivered a package. It contained a piece of brown paper and five curved lines. Nothing more. Clearly I was stupider than most.

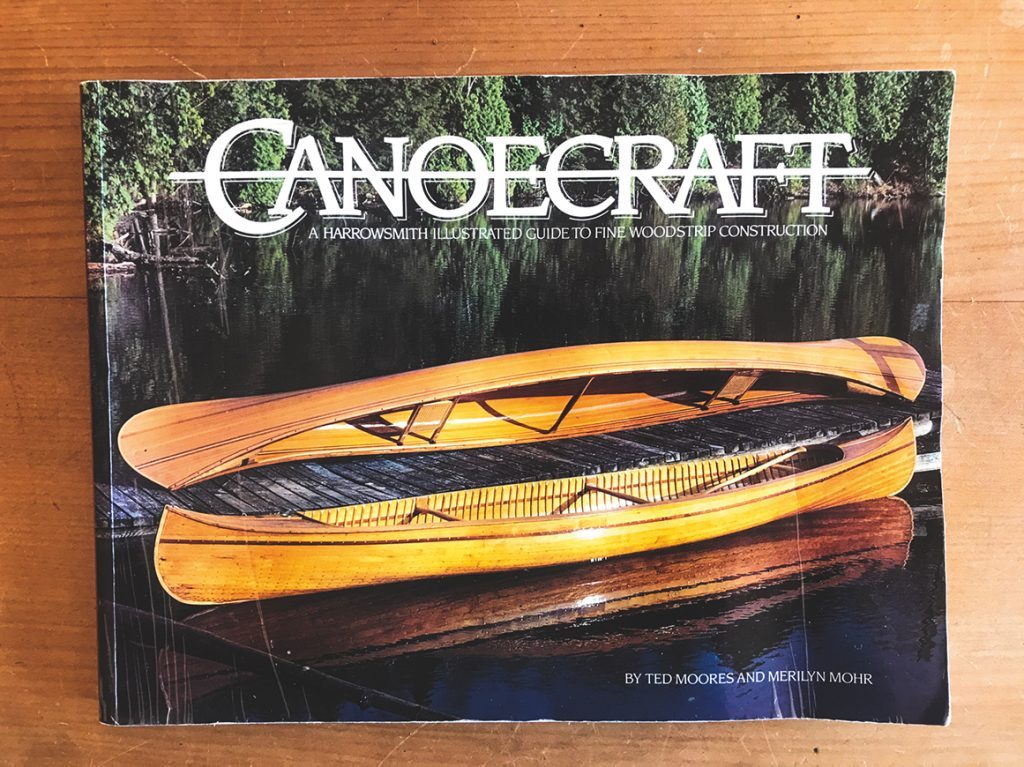

Weeks later, after phone calls and letters to Canada, Canoecraft – A Harrowsmith Illustrated Guide to Fine Woodstrip Construction by Ted Moores, arrived.

I had a lot of learning to do.

Over the course of a year I learnt how to build a strongback, how to lay out the lines, and proceeded to build up the hull of a Bear Mountain Hiawatha canoe.

Later I learnt that steam-bending, holding and clamping in place 5m strips of boiling white ash was very difficult, but also rather therapeutic.

I learnt that trying to poke lengths of white ash into boiling water in a coffee pot set on a Primus stove with down-piping clamped over the spout should not be attempted with standard plastic pipe – it melts and collapses.

Steam, melted plastic, a roaring primus, boiling water, flaming rags and hot wood make for quite a night of swearing. I also discovered it’s best to have a fire extinguisher close at hand.

I learnt woodworking: sanding, planing, steaming, sanding, clamping, gluing, sanding, screwing, sawing, chiselling, vacuuming, fibre-glassing and more sanding – all processes you have to go through to discover the real fear and joy of boatbuilding.

Reading the Canoecraft manual over and over and over again, to make sure I hadn’t done something stupid and irreversible, was both wise and time-consuming. A year of nights, frights, fun and bewilderment meant that eventually the gorgeous woodgrain was finally exposed under smooth epoxy, fibreglass and varnish. It glowed.

I took it to Lake Pupuke. With some trepidation and urgings from family and friends, I lowered it into the water for the first time. It floated. It was straight. Balanced. Poised even. My guesses for the seating positions were perfect. It looked incredible!

There it was, floating on a sun-sparkled, weed-fringed lake. All I could think of was my dad, who had passed a dozen years before. I burst into tears. Who knew that boatbuilding was so damned emotional?

The canoe got praise as a work of art, with comments like “that belongs in the lounge, not the lake” and it took a while to comprehend that I had built this thing of beauty from scratch.

Over the years the canoe got some use, was taken to lakes and rivers, but slowly, over time, I used it less and less. Always difficult to store without a garage, it hung at head height athwart my basement shed for 20 years, causing thousands of head knocks.

Two years ago I moved it from the shed and hung it from two hooks against the pool fence, while I completed a clear-out of fishing and hunting gear, woodworking and motorcycle kit – and trunks of tools.

My family loved seeing the boat on the fence – once again it was visible to all – but I had a nagging feeling about the sun and the wind and dirt… Still, I could now work in the shed without needing doctor’s visits for concussion. A win.

One night a year ago a huge wind flung the boat across the yard. It cracked the epoxy coat at the starboard tumblehome waterline. Damage looked minimal, so I found some varnish, covered up the crack and popped it back on the wall.

Bad move.

During Covid-19 I decided to give it a well-deserved clean. I noticed immediately that my neglect had seriously damaged the canoe – once again my fault was manifest. Cleaning away the grime revealed that the varnish had peeled off and bubbled in places, the cedar was fading and there was some yellowing of the epoxy. There was black mould along the white ash gunwales. It looked terrible, but even worse was to come.

The earlier crack had split open, allowing water into the cedar, leaving spreading water stains that were unsightly and nearly impossible to fix without stripping out entire boards or, even more drastically, by cutting a circular hole and rebuilding the hull inside and out with fresh wood, glass and epoxy. The cure, I felt, would look just as bad or maybe worse.

As I spent more time with the boat I slowly realised it was never going to be restored to showroom finish. And yet, it now had ‘life’ and patina. I remembered every mark and blemish that had come from love and use. Trying to remove 25 years of history was not only pointless, it was an insult to all the memories we’d made together.

Checking over the internal section I happily concluded the damage caused by the external crack was not visible – the discolouration hadn’t reached the core cedar inside. I decided an outside repair he would restore hull integrity and any repair marks would be a testament to care – not neglect. Little did I know!

As I stripped the varnish worse damage came to light. The varnish stripper I’d ordered online stated it was safe for use with fibreglass substrates. It wasn’t. Removing the old layers of varnish lifted the fibreglass under the epoxy. In several places on the upturned hull, especially at the centreline, the varnish stripper had penetrated the cloth, dissolving the original epoxy and exposing the milky-grey colour of now dry fibre.

Fortunately the epoxy kit I ordered finally arrived and I managed to restore 98% of the surface. But at the waterline entry (stem and stern) nothing would save it from lifting and splitting – the fibreglass had to be cut out with a sharp craft knife, taking care not to cut into the soft cedar, or the white ash of the stem.

I cut away the old mat, sliding a scalpel blade under the old fibreglass and cut into the ‘good’ areas, leaving neat edges that could be replicated with new cloth laid directly onto and over the joins, before being sanded back in preparation for new epoxy and varnish finishes.

Of course, I had no epoxy or fibreglass mat on hand, so I ordered it online but, after paying, discovered it could not be shipped until we reached Alert Level 3 at the earliest.

I spent many weeks looking at my boat, languishing with tape over the exposed wood surfaces. Three and half weeks of perfect boating weather passed as I gazed impotently at calm seas and blue sky. Couldn’t fish, couldn’t go boating, couldn’t fix the boat. Time slowed – never seen such a run of perfect weather. Gah!

When Alert L3 finally arrived so did the mat and epoxy. Having fixed the epoxy finish with two new slip coats, the hull is back and intact. The glass repairs have been sanded smooth and clean.

But where I cut out the fibreglass for the repair on the belly there is a letterbox-shaped dark patch where the new glass has been fixed in place. The epoxy reacted with the wood that was exposed to water, making it many shades darker.

At first I was really annoyed, even though the repair was as smooth and clean as the original hull, but it does serves to remind one that boats and other gifts of life have to be cared for in a timely manner.

During the rebuild I came up with a plan. I built a backrest that includes a small engine mount and purchased a small electric motor and a mobility scooter battery. I made a box that will swing under the forward seat to house it. Wires run under the gunwale.

As I get older paddling against headwinds and current is less and less appealing. This new configuration should allow me to access lengthy waterways, hopefully teeming with trout.

So, as soon as the rain passes, I will be ready to complete the final coats of varnish and then a final polish. I think it’s fair to say that neglect is not a trait I wish to have as a legacy. So, dammit, I am going to have to build a garage with rafters in the roof to haul my woody girl up into! Head-bashing needs to be a thing of the past, not the boat itself.

Did it cost more than I thought it would? Of course. Was it worth it?

Completely. She helped hold me and my history together, and when we are together, I get a sense of peace and calm I find almost nowhere else.