Next-generation technology has opened the door to unprecedented advances in marine electronics and engineering, bringing boaties greater safety and convenience than ever. Whether you’re looking to upgrade old gear or add allnew capabilities, you’ll find plenty of choice this coming year.

Technology continues to evolve at lightning pace, and that’s great news for boaties. Curious what the future holds? Here’s just a sample of the new high tech we could be seeing on the water in the years ahead.

If you think you’re hearing about more new technology these days, you’re right. Solar panels, electric cars, virtual meetings – even mobile phones – were all once considered far-fetched ideas straight out of science fiction novels. They have all since gone on to become part of everyday life. So, what’s next?

Where boaties are concerned, the future is full of amazing new technologies. Care for a sneak peek? Here’s just a sample of what’s in development right now.

MAGNETIC SHORE POWER SYSTEMS

One of the realities of having electricity anywhere near water is that corrosion is inevitable, and that in turn can lead to short circuits. In the case of shore power systems, corrosion can cause serious fires if a connection arcs or overheats.

A Canadian company called VoltSafe has developed a new magnetic plug design that eliminates the traditional prong-and-socket configuration altogether, creating what it says is the safest shore power system in the world. Inspired by the magnetic power cords used on Apple laptop computers, VoltSafe invented and subsequently patented a high-voltage magnetic connection that can provide 30, 50 or 100-amp shore power – or even charge an electric boat – without risk of arcing or corrosion.

“The plug will only let power flow once the outlet recognises an exact electrical signature from the plug, and this happens in less than five milliseconds,” says VoltSafe CEO, Trevor Burgess. “So, if you accidentally drop your plug in the water, it’s not going to pop all the breakers or electrocute anyone.”

The company is now talking with boat builders and marina pedestal manufacturers to bring the system to market.

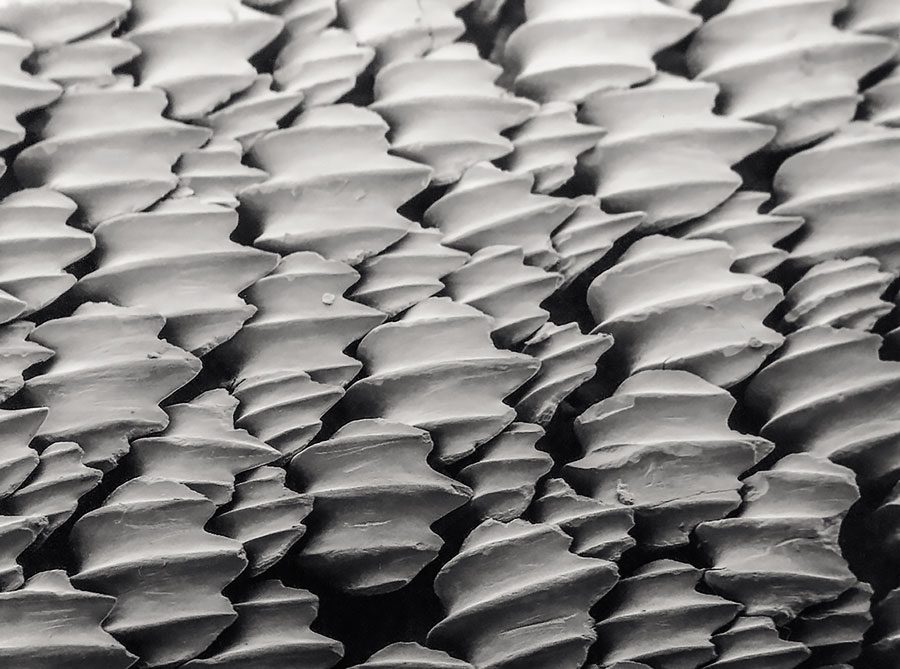

HULL COATING INSPIRED BY SHARK FIN

Most boaties are familiar with stepped hulls, which use an irregular shape to break surface tension and increase performance. In Europe, German engineering firm BASF is achieving even better results by replacing the single abrupt step with millions of much tinier ones.

Inspired by the way sharks can swim at high speeds for long distances with minimal effort, the company has developed a super-slippery film that’s covered with tiny, diamond-shaped structures inspired by the sandpaper-like denticles found on shark skin. This film can be applied to any hard surface to reduce drag and, as a result, significantly lower both fuel consumption and emissions.

In lab tests the new film proved so successful that the German national airline, Lufthansa, has entered into a programme to conduct real-world testing on one of its cargo jets. Initial results have been encouraging, meaning the drag-reducing film could make its way to market in the very near future.

NEXT-GEN STABILISERS

Let’s face it, it’s hard to have fun on the water when the boat’s pitching up and down in rough seas. But a new stabiliser technology aims to tame the waves by suspending the yacht above them.

The Martini concept – a collaboration between Servo Yachts and Shuttleworth Design – uses parallel pontoons to form a catamaranstyle hull, with the passenger compartment suspended between them on shock-absorbing legs. Imagine a spider straddling a pair of matchsticks and you get the basic idea.

As the pontoons heave up and down in the waves, their motion is absorbed by the articulated legs, leaving the yacht itself level and still at all times. The unique suspension system is said to deliver the smoothest possible ride in rough seas.

Servo Yachts has tested a series of prototypes and is now partnering with Shuttleworth Design to develop a pair of luxury yachts – dubbed the Martini 6 and the Martini 7 – around the concept.

SOYBEAN SEAT CUSHIONS

Foam seat cushions are made from oil, and with prices skyrocketing these days, boat builders are open to alternatives – like plant-based resins made from soybeans.

The idea of using plant-based resins isn’t new – Ford first tried them a dozen years ago, when it put soy-based foam in the seats of its 2008 model year cars, including the flagship Mustang. More recently, Toyota and BMW have also adopted the use of plant-based resins in their own vehicles.

North American boatbuilder Campion Marine started using soy-based seat cushions in 2016 and won a Boat Builder Award for Excellence at METSTrade the following year as a result. As oil prices continue to rise, it’s very likely other companies will adopt foam cushions made from soybeans to curb costs and reduce their reliance on fossil fuels.

CHARGE YOUR ELECTRIC BOAT IN 5 MINUTES

THE MAIN KNOCKS against electric boats (and electric cars) are limited range and that they take a long time to recharge. Researchers at Purdue University in the USA are aiming to change that with a new type of power cable that could cut recharge times to just five minutes.

Charging time is limited by the capacity of the cable linking the boat to the power source. Pushing more power through the cable speeds the process, but also generates more heat. Too much, and the cable melts.

The Purdue team have developed a water-cooled cable that can take much higher voltage without overheating – allowing charge times 20 times faster than possible with a standard power cable. Patents are pending, and investors are standing by – including major electrical equipment companies.

HIDING BATTERIES IN SAILS

Electric boats need big battery packs, and they can suck up a lot of interior space – especially on sailboats, where there isn’t much room to begin with. But a new flexible battery technology could eliminate that problem by allowing a vessel’s sails to store all the energy it needs.

Researchers at the Nanyang Technological University in Singapore have developed a flexible, lightweight and paper-thin battery that can be rolled, folded, twisted or even ripped without impairing its ability to supply power. This allows the battery to be integrated into flexible structures like sails, or even a canvas top. Combined with solar panels and an electric motor, the flexible batteries could theoretically give any sailboat unlimited global range.

CREATING FUEL FROM WATER

Several leading engine builders are touting hydrogen gas as a replacement for diesel and gasoline in engines, given that it’s cheap, widely available, and the only emission it produces is steam. Further, engines running on hydrogen would only require minor modifications from existing ICE designs, making the transition fast and cheap.

Like any other propellant, hydrogen would need to be carried onboard in a tank, which takes up space and delivers a finite volume of fuel. But a new technology being developed in the US to strip hydrogen from water could theoretically give boats, yachts and commercial ships unlimited range, allowing them to create their own fuel on the fly as required.

By introducing water to two key elements – aluminum and gallium – researchers at the University of California found they were able to induce a chemical reaction which produces significant volumes of hydrogen gas that can be used to power a vessel.

Best of all, the reaction takes place at room temperature, eliminating any need to heat or cool the water in order to achieve a result.

Whether or not their process for generating hydrogen fuel on demand can be scaled to commercially viable levels remains to be seen. The researchers have filed a patent application for the process, however, so clearly, they believe it possible for boats to produce their own fuel on the go while enjoying unlimited range roaming the oceans of the world.

PAINT-ON SOLAR PANELS

Not everyone likes the look of a solar panel array. But what if the panels could just be painted on, and in any colour you like?

That’s the goal of researchers at the University of Toronto in Canada, who are developing paint-on solar panels using quantum dot solar cells. Quantum dots are tiny, light-sensitive grains small enough to be mixed into regular paint. They are more effective than traditional solar panels because they respond to a broader range of light wavelengths and can be used to coat the entire vessel.

Even better, quantum dots are cheap, so they offer a low cost per watt of power – a key factor in making the technology commercially viable. The technology has already attracted interest – and investment – from major automakers.

FULLY AUTONOMOUS BOATS

Progress toward the development of fully-autonomous boats took a giant leap forward in January this year when a Japanese car ferry completed a 240km voyage through the Iyonada Sea, successfully departing port, navigating the crossing while avoiding other traffic, and docking at its destination – all without human intervention.

Built by Mitsubishi, the Soleil executed several automated manoeuvres in the course of its voyage, including high-speed navigation at speeds of up to 26 knots. The electronics used to guide the 222m vessel include infrared cameras that can detect other ships in even total darkness, an automated ship navigation system collision avoidance capability, and an advanced automated port berthing/unberthing system that provides fully-automatic docking.

The Soleil ferry began navigating with a human crew in July 2021, allowing the vessel to compile six months of passage data in preparation for its fully-autonomous navigation. That data bank can now be shared among other autonomous vessels travelling a similar route or visiting the same ports. The long-term goal is to create a global, shared library of navigation and port data that can be collected by and shared among all autonomous vessels – updating the data bank in real time to reflect any changes.

Scaled-down versions of the system could also allow fully-automated leisure boats to handle the driving while their occupants relax and lay out in the sun. Industry analysts say that automation systems could be just the ticket to encourage more people to come boating by eliminating anxiety over docking or learning navigation skills.

INSULATION YOU CAN EAT

Boats use a lot of insulation, whether it’s to make overnight accommodations more comfortable, or to cut noise from the engine compartment. But traditional insulation isn’t the nicest stuff from an environmental perspective, leading a group of German scientists to experiment with more ecologically-friendly alternatives – like popcorn.

Researchers at the University of Göttingen in central Germany say granulated popcorn is a great insulator that actually outperforms the stuff already in use. Further, popcorn can be formed into sheets or applied with a spray gun for easy installation. It’s highly fire-resistant, costs pennies, and is widely available. Best of all, at the end of its life popcorn insulation is fully biodegradable. You can even eat the stuff.