Marina expansions, while exciting for berth holders, often come with challenges.

The Fairway Bay Marina expansion, managed and constructed by Bellingham Marine, faced several obstacles. One of the most significant was the task of removing old piles from limestone bedrock and placing new piles into the marina floor, which consisted of a solid base akin to low-strength concrete.

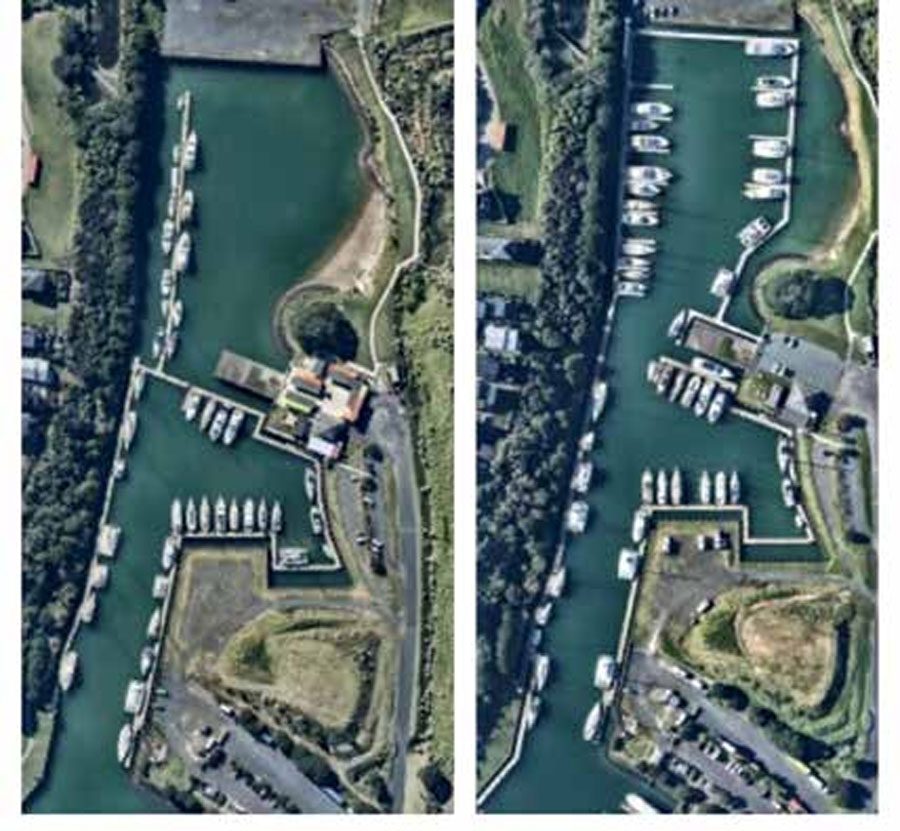

Fairway Bay Marina undertook the marina expansion project that commenced work in June 2022 and successfully concluded on schedule in December last year. This expansion aimed to elevate the marina’s facilities and address the increasing demand for berths, especially within the larger 20 and 18-metre catamaran market. Situated at the end of the Whangaparaoa Peninsula, the marina enjoys a prime location with direct access to our world-class Hauraki Gulf.

THE LIMESTONE BEDROCK CHALLENGE

One of the most significant challenges encountered was the need to not only remove old piles but also secure piles into the unforgiving limestone bedrock. Removing the old steel piles effectively cemented into the marina floor required high-capacity vibration equipment, and placing the new piles required drilling 400mm diameter pile sockets into layers of limestone that were rock-hard, which posed considerable difficulty.

Craig de Wet, Bellingham’s Senior Project Manager, recalls the lessons learned from a previous project at Gulf Harbour Marina. “We learnt from drilling the pile sockets for T Pier meant we had to find another way,” says Craig. The issue revolved around the socket spoils fouling the auger, leading to hours of constant cleaning and slow progress.

To address this challenge, the project team modified the drilling auger to direct a flow of compressed air down through the auger centre during operation. This effectively flushed out the excavated material as the socket was being drilled, greatly enhancing the efficiency of the drilling process.

RE-PURPOSING OLD MATERIALS

Sustainability played a pivotal role in the expansion project. Instead of disposing of old pontoons and piles, one-third of the existing marina was repurposed into the new expansion. This approach not only reduced cost but also reduced the environmental impact. Industry standard marina pontoons are made up of a polystyrene core encased in concrete and both materials are challenging to dispose of or recycle. The project therefore accommodated the existing marina structures seamlessly into the new expansion.

The Fairway Bay Marina expansion, despite its challenges, stands as a testament to innovation, efficiency, and sustainability. It pays tribute to the dedication and problem solving spirit that drives marina construction in challenging environments. BNZ