Although windscreen wipers are a legal requirement on cars, many boats, especially small to medium models, lack these. At sea there aren’t many pedestrians wandering across your path, but a good view ahead is essential – particularly in bad weather or low-light conditions. Story by Norman Holtzhausen.

Fitting a wiper system is a no-brainer, especially once you’ve tried negotiating a crowded waterway in driving rain and not been able to see what lies ahead. This happened to me recently with a friend’s cabin boat, and he confessed that when he purchased the boat his budget hadn’t extended to this ‘luxury’ item. But after our experience he realised it had moved from the luxury to the necessity side of the equation. So, we went to see what was available for retrofitting.

Four elements are required: the wiper motor, the sweep arm, a wiper blade and some sort of switch or controller if your current switch panel doesn’t have a suitable button. The marine chandler where I seem to spend far too much money had several options on display.

These ranged from $129 for the simplest kit (containing a compact 12v motor with fixed speed and sweep angle, and a 350mm arm and blade) up to almost $700 for a heavy-duty, self-parking, all-stainless motor with dual speed, adjustable wiping angles and thermal cut-out.

Before selecting a model you need to consider the window area to be covered. A single sweep arm wipes in a curved arc, like most car windscreen wipers. On the other hand a pantograph arm is made up of two parallel bars which keep the blade in the same vertical orientation throughout the sweep.

It therefore wipes an almost rectangular area and achieves a higher coverage of the total window area. The pantograph requires a stronger motor and also a special mounting bracket, and so is more expensive.

The second decision is locating the motor and how long the shaft needs to be to properly reach the cabin-top hole. If space is tight the motor can actually be fitted through a hole in the glass, although this is hard to retrofit if your window is toughened glass.

In our case we had a suitable ‘eyebrow’ area in the cabin roof above the window where a hole could be cut through the fibreglass. The advantage of this option is that the motor unit wouldn’t impinge on the view, although running the wiring down through the roof was going to be slightly more complex.

In our case we had a suitable ‘eyebrow’ area in the cabin roof above the window where a hole could be cut through the fibreglass. The advantage of this option is that the motor unit wouldn’t impinge on the view, although running the wiring down through the roof was going to be slightly more complex.

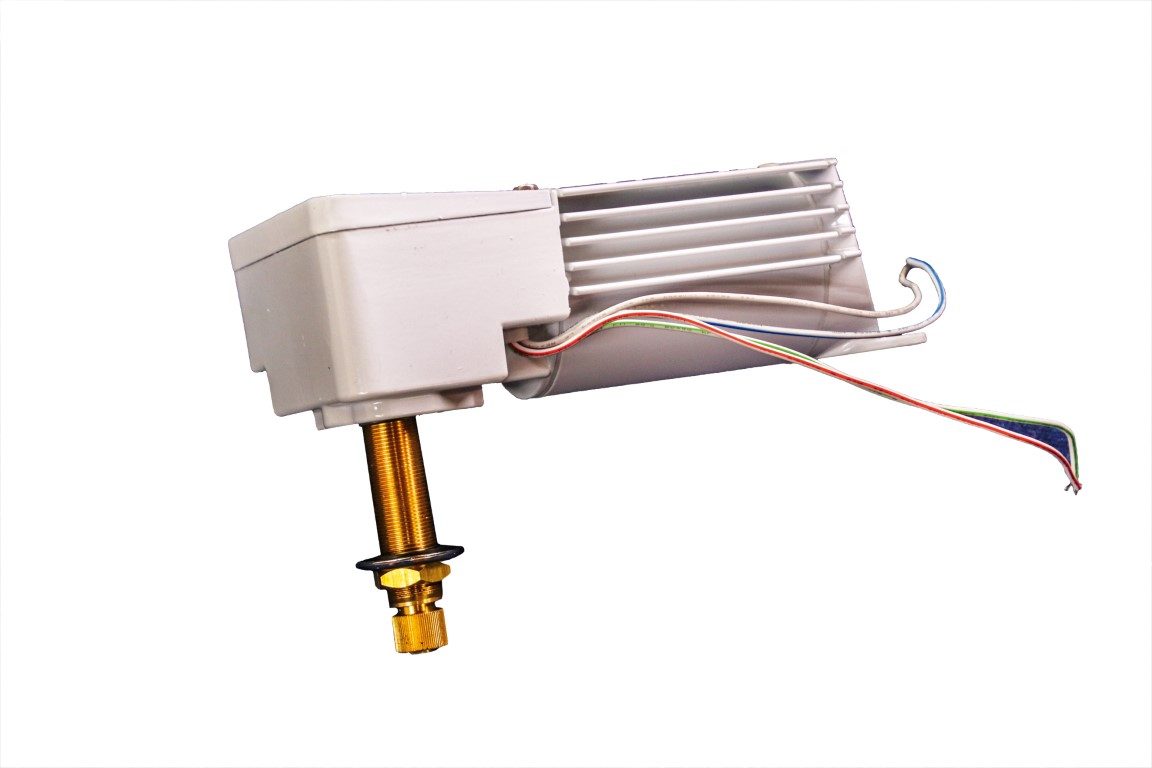

We decided against the entry-level kit option because we wanted the superior coverage of a pantograph. Also, my experience with the cheaper ‘coffee-can-style’ motors is that water eventually wicks down the drive shaft into the motor body, causing corrosion. The larger offset-style motors prevent this by having the motor geared at right angles to the drive shaft, so any moisture doesn’t get into the electrics. Most of the mid-to-upper range motors have a variable sweep angle that can be set to a range of values, although they come factory-preset to either 80o or 110o . They also come in different shaft lengths, and this of course depends on the thickness of the cabin/ rooftop construction. We chose the 110o model with a 50mm shaft length, although we knew we’d need to adjust the sweep angle once it was installed.

The second variable is the length of the arm, and there are two common models. The shorter one is adjustable from 31 to 43cm in length while the longer ranges between 43 and 56cm. In our case we needed the longer one for our very large windscreen area, and also chose the longest 50cm wiper blade.

Our immediate requirement was to get a wiper installed for the helm position – and given the limited budget we purchased a single motor, pantograph arm and wiper blade for around $250. Later on we may fit a second wiper to the passenger side window.

The final component required was a control switch. The motor itself has two speeds and also an auto-park feature – the blade moves out of the way to one side even when you turn it off mid-wipe.

So, a simple three-position toggle switch (off, slow, fast) would have sufficed. But a range of electronic switches are available that also offer a variable wiper delay, so it can be set to wipe between 5 and 20 seconds. In the end we chose a compact wiper controller that has switching capability for up to three wipers, to accommodate that future passenger-side wiper.

INSTALLATION

The hardtop’s vinyl lining had to be cut to gain access to the inside surface of the fibreglass. We will make good on this lining afterwards, tucking it up against the motor body. Installing the motor required one 16mm hole for the drive shaft. A second, smaller hole was needed for a locking screw or a bolt to hold the other end of the motor. In our case the fibreglass was thick enough for a small screw to be fitted without protruding through the outer gel coat, preventing any water ingress.

With the motor fitted loosely in place, I went out the front of the cabin. The pantograph has a short bracket that’s held in place over the motor shaft by a retaining nut. Another small locking screw into the cabin surface is required to prevent this bracket from twisting. After drilling and fixing this with sealant we could then snug up the nut on the motor shaft, ensuring nothing would move. We fitted the wiper arm and wiper blade onto the shaft splines.

Depending on the type of motor and the requirements of the controller, three or four wires are needed from the motor to the control panel. We ran two lengths of twin-core tinned marine cable. These motors don’t draw much current (a 6-amp fused is specified) and so 1mm cable was adequate for the short distance it needed to run.

Installing the controller required a 50mm square hole near the helm, which should have been an easy job. Unfortunately, my jigsaw would not fit to cut the horizontal lines, and too late I remembered I’d recently bought a Bosch cordless nanoblade saw which would have been perfect for this job. Instead I had to drill a line of holes and join them up to make the top and bottom cuts. Sometimes we make things harder for ourselves than they need to be!

Following the instructions that came with the motor and the controller it took me about half an hour to get the wiring sorted, although running the cable down a channel in the corner of the window was a bit tricky.

A quick test confirmed everything was operating as expected, and we operated the motor to check where the wiper started and finished each sweep. It looked like we needed about a 90o sweep angle to cover the maximum window area without the blade catching against the window surround.

Adjusting the park position is done by adjusting the position of the arm on the shaft splines, and we would do that afterwards. First, we needed to set that sweep angle. The supplied hex wrench undid the four recessed bolts and the cover came off the wiper motor gearbox. A pair of pliers took care of the circlip, and we could re-position it to the 90o hole. We put the circlip back but delayed replacing the cover.

Adjusting the sweep angle also changes the park position, so we removed and replaced the wiper arm on the splines to suit the new position. After securing the grub screws to keep it in place, we carefully operated the wiper while holding it carefully just off the window. Luckily, we had both the angle and park position correct, so it wipes to within about 5cm of each side of the window and ‘parks’ neatly on the starboard side.

Adjusting the sweep angle also changes the park position, so we removed and replaced the wiper arm on the splines to suit the new position. After securing the grub screws to keep it in place, we carefully operated the wiper while holding it carefully just off the window. Luckily, we had both the angle and park position correct, so it wipes to within about 5cm of each side of the window and ‘parks’ neatly on the starboard side.

All done! We tightened everything up, tucked the wiring neatly into the channel and vacuumed up the dust. The only job still to be done is fixing the vinyl on the roof (we cut too much off at the start…).

The entire installation took about two and a half hours. The wiper, arm and blade cost just under $250, and the controller a further $149.99. If we add the passenger side wiper we won’t need another controller, of course, so that will be both cheaper and considerably quicker to install.

The entire installation took about two and a half hours. The wiper, arm and blade cost just under $250, and the controller a further $149.99. If we add the passenger side wiper we won’t need another controller, of course, so that will be both cheaper and considerably quicker to install.