Wet bilges may have been acceptable back in the olden days when everything from the galley sink to the fridge drain emptied into the (smelly) bilge, writes Birgit Hackl – the mess was simply pumped out regularly – but standards have changed, environmental issues must now be considered, and most boat owners nowadays want a dry bilge. Story by Birgit Hakl.

In most boats an automatic pump goes off, usually connected to an alarm and/or a blinking light, when water is detected in the bilge. On our 30-year-old Sparkman & Stephens the stringers and frames form little compartments in the aluminum hull that are not connected to one another. Water gets trapped in them and we can’t use the big bilge pump (located at the hull’s lowest point) to get rid of it.

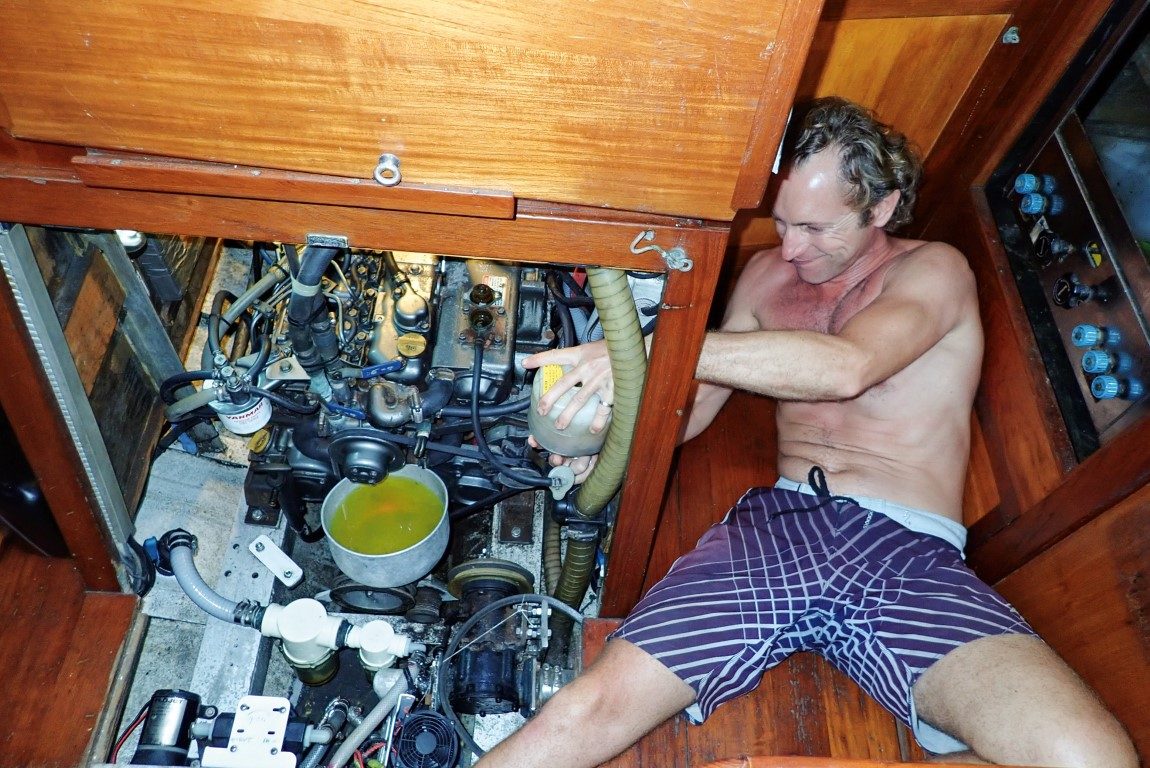

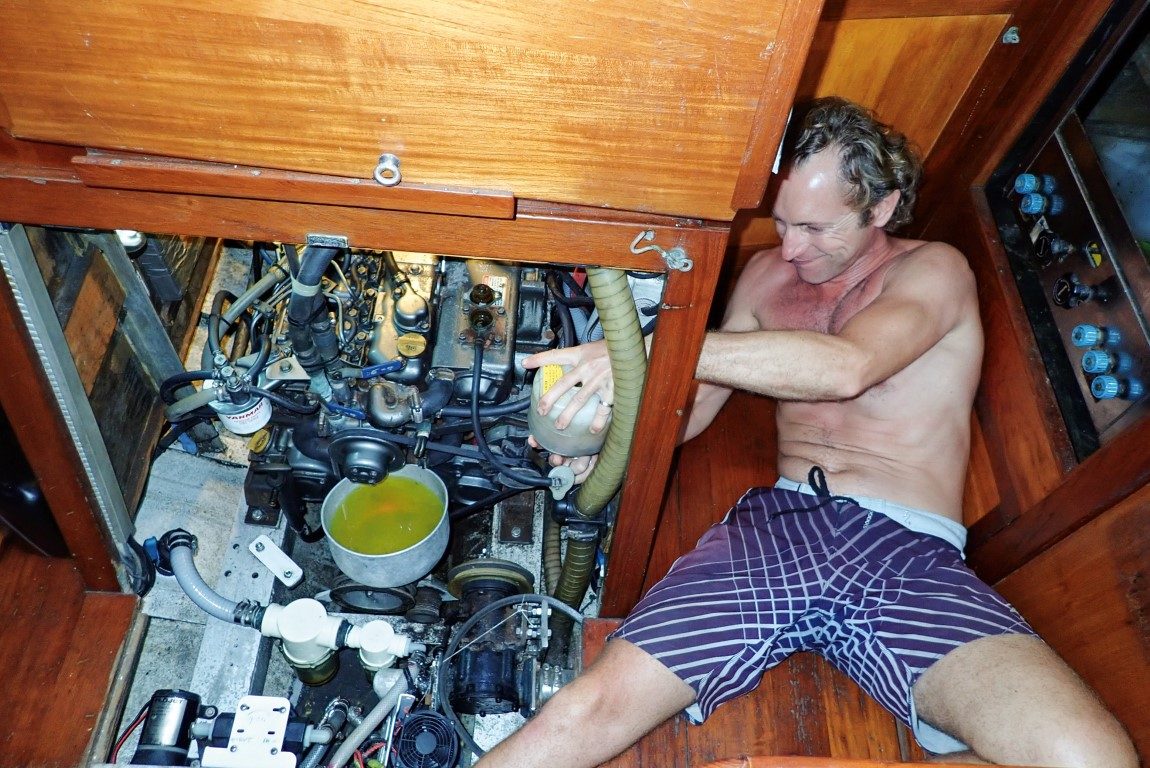

This design is meant to make the source of any humidity easily traceable – a nice thought, but also a major pain when you must mop up the water by hand. This is especially so for water beneath the engine where only the nozzle of a wet/dry vacuum cleaner or a tall person with very long, slim arms can reach. Belly down, bum up, face on the floor, shoulder twisted, arm scratched on sharp metal and a hand stuck in the bilge – it’s neither graceful nor fun and should be avoided wherever possible!

Over the years, we’ve had many incidents of water trapped in the bilge, some caused by our own stupidity, others by technical failures that might have been avoided by thorough checks or better maintenance. Here’s what we’ve learned.

Leaking freshwater system

Motoring at night on our very first passage after buying our yacht Pitufa, we newbie sailors panicked when the water alarm went off. Floorboards up – so much water! Where’s it coming from? Fresh or salty? Just one way to find out – stick in a finger and taste!

Retching and spitting was followed by relief that it was fresh water. And we soon found the source: the engine had heated up the boiler [hot water cylinder], causing the newly installed hoses to expand and one to slip off its collar. The pressure pump then dutifully emptied both fresh water tanks into the bilge.

We learned: tighten hose clamps properly to keep them from slipping; close connections between water tanks so that they don’t empty together in case of failure; and turn off the pressure pump while motoring…

Open hatches

An all-time favourite we keep repeating is leaving the hatches open. At anchor a proper downpour soaks the cushions and eventually seeps into the bilge. At least it’s only fresh water. At sea it’s less fun to have a wave spitting through a hatch. We still struggle to always remember to close the hatches before leaving the anchored boat – and to close them during passages whenever (or rather before) conditions get rough.

Leaking mast boot

Many boats leak water through hatch seals and along the mast whenever it rains hard. We always deemed ourselves lucky, since we never had that problem – until the deck was constantly awash for days on a tough upwind passage from Tonga to Niue. Quite some water made its way into the boat, seeping in along our (keel-stepped) mast.

We learned that a hypalon collar is a long-term, reliable solution. We glued and clamped hypalon around the mast and water has never entered there since.

Watermaker brine

On our first watermaker, the hose for the brine was connected to the galley sink. While heeling on a passage, air bubbles blocked the sink drain and brine eventually filled the sink, then flooded, first the fridge, and finally the bilge before we finally noticed a problem. Major mess!

We learned it’s much safer to have dedicated through-hulls for the watermaker, which we installed together with our new Spectra watermaker.

Sink fountain

Sailing close-hauled on the port tack, the sink outlet for our bathroom dips below the waterline, resulting in an impressive geyser spurting from the drain with every wave.

We learned: always close the drain through-hulls on the downhill side when the boat is heeling (and don’t forget about the other side before tacking!).

Dripping or drip-less shaft seal

Stuffing boxes are just tight enough to provide a watertight seal when the shaft is stationary, so an unattended boat will not sink, but loose enough to drip slightly when the shaft is turning, to lubricate and cool both the shaft and the packing material. That’s why owners of boats with stuffing boxes always have some water collecting beneath the shaft.

Our boat came with a drip-less face seal, which is supposed to be dry – and it was for many years. But eventually it did start dripping, so we ordered a new seal, but didn’t get around to installing it for another year. We just kept mopping up…

We learned: we were lucky – shaft seal failure can sink boats, so regular checks and fitting replacement seals when required are a must. Old salts recommend carrying bicycle tubes to stop water inflow in an emergency.

Rudder seal

Buckets of water sloshing around under the engine on a downwind passage sent us frantically tracing our frame compartments until we found the culprit: the neoprene collar around the rudder stock had ripped and the high waves of the following sea were forcing water in. We hove-to and super-glued the collar aboard our wildly pitching and rolling boat to affect a temporary repair (seasickness guaranteed), replacing the collar later once we were safely at anchor.

We learned: regularly check the rudder stock seal and replace as necessary – preferably while comfortably at anchor in a calm bay.

Engine

A leak in the seawater cooling system not only causes a flooded bilge, but usually severe overheating and potentially a ruined engine. Fortunately, we have yet to experience any such issues, but it’s best to check the cooling system regularly to avoid a major catastrophe. Unfortunately, by being good and regularly changing coolant, impellers, hoses, etc., some water always drains into the bilges. It’s unavoidable, as is cleaning up afterwards…

Bilge pump

Some friends installed an automatic bilge pump connecting the outlet to the galley drain. They were ashore when it turned on, filled the hose with water, turned itself off automatically, and seawater siphoned back into the boat.

They just got back onboard in time to yell for a tow and managed to reach the dock where firefighters were waiting with a pump before the yacht foundered. It’s ironic the bilge pump attempted to sink the boat!

We learned: always make sure you have a vented loop in hoses that might siphon water back, or better still – for bilge pumps – attach the outlet to a separate hose that empties above the waterline.