New Zealand’s largest marine electronics manufacturer – Electronic Navigation Ltd (ENL) – is celebrating its 75th anniversary. Its flagship product – WASSP – is a sophisticated sonar technology exported to 30 countries. It – and the company – carry a fascinating genesis.

ENL, says managing director Gareth Hodson, was formed in 1945 by a trio of entrepreneurs – a doctor, an accountant and a businessman. “They called it Electronic Navigation from the get-go – operating from a house in Auckland’s Grey Lynn – but they actually dabbled in a range of electrical products. The main one was a quick-release mechanism for the start gates at horse-racing tracks.”

Mainstream ‘electronic navigation’ began with the development of a double side-band radio for the shipping and commercial fishing sectors – a strategy that gained impetus when an ex-Navy man – Commander Jack Williamson – joined the company in the 1960s as general manager.

“ENL is often described as a family business,” says Hodson, “but we only got involved when dad joined as a part-timer a few years later. He was a radar engineer and, like most of the other six employees, an ex-Navy man.

“He worked his way up – sales manager, general manager – and then in the mid-80s he bought the company outright. The timing couldn’t have been worse. The financial crash and Muldoon’s draconian tax regime created a really challenging business environment and it put huge pressure on the family.

But we survived.”

R&D

While it’s impossible to separate R&D from the company’s DNA, he says, it first flourished with the orange roughy fishery in the early 90s. “Trawler captains were struggling to deploy their nets accurately. Shooting the net over a pinnacle where the shoals congregated was a real hit-or-miss affair – mainly miss.

“I’d just joined the company and cut my teeth on NetLink –

a software tool we developed to run in conjunction with Furuno technology. The Furuno relationship goes back a long way – we’ve been the exclusive distributor since 1964 and are, in fact, the world’s oldest Furuno agent.”

Netlink used pressure sensors that interfaced with the software, and it gave the fishing crews crucial information about the depth and velocity of the net. Featuring graphics and modules, it offered an easy user-interface – and it made a huge difference.

News of the product’s success spread quickly and Hodson was dispatched to help the Canadian fleet fish for orange roughy in the Atlantic. The Canadian and Spanish fleets had exhausted their cod resource on the continental shelf – it decimated their industry – and didn’t want to repeat the mistakes.

“It was an enormously valuable experience because it introduced me to the concept of a sustainable fishery – and that philosophy has shaped our modus operandi ever since. Back in New Zealand, it gave us a better understanding of our commercial fishing industry and the Quota Management System.

“This was crucial for the development of our technology – and it ultimately led to the evolution of WASSP. Our focus changed – the objective became giving the fishermen the technology and tools they needed to operate more efficiently and sustainably – and reduce by-catch.”

R&D added another string to the company’s bow in the mid-90s with a new software product called Data Master. It was born when GMSS (Global Mobile Satellite System) became mandatory on ships. In those pre-EPIRB days distress signals were generated from single-sideband radios. Data Master monitored those signals across the Australasian region. It was installed by the Navy, the Maritime Safety Authority and its Australian equivalent (AMSA).

But NetLink and Data Master were only curtain-raisers for the main event.

WASSP

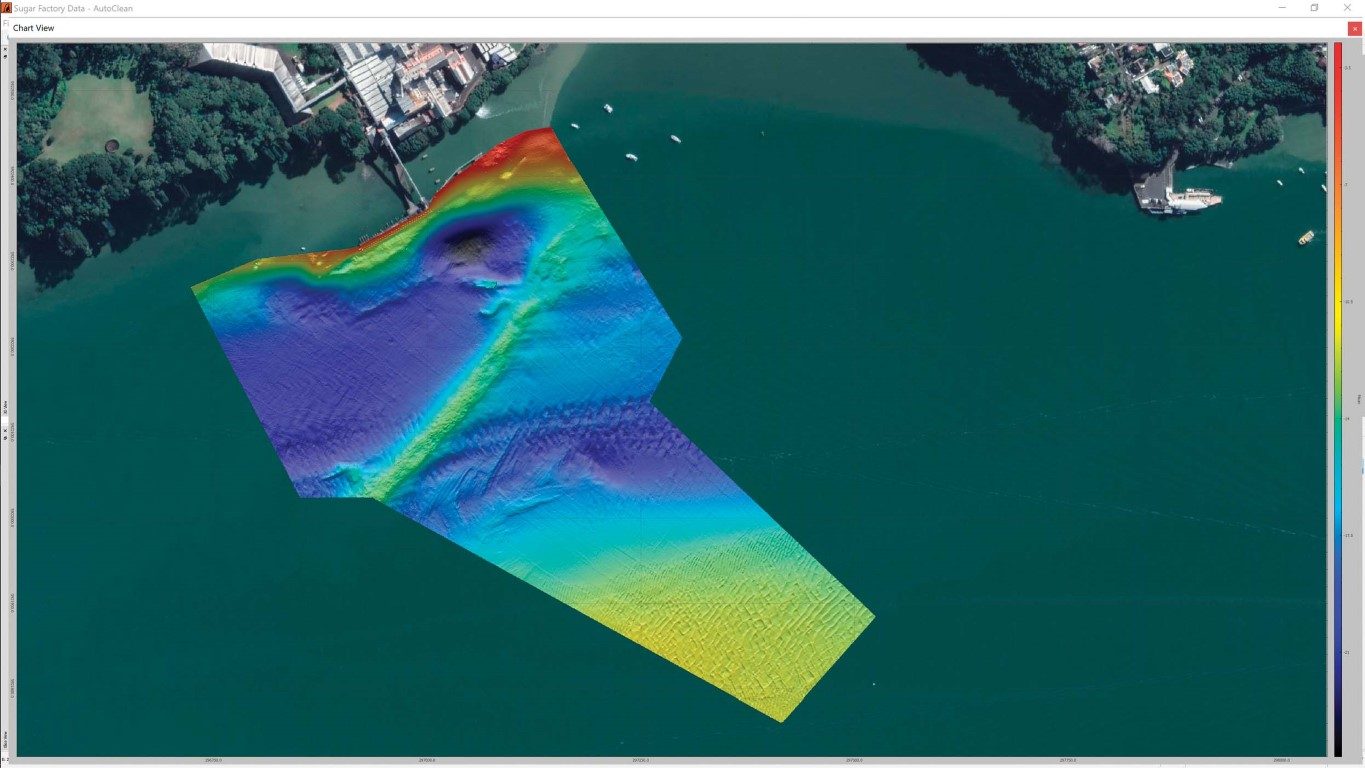

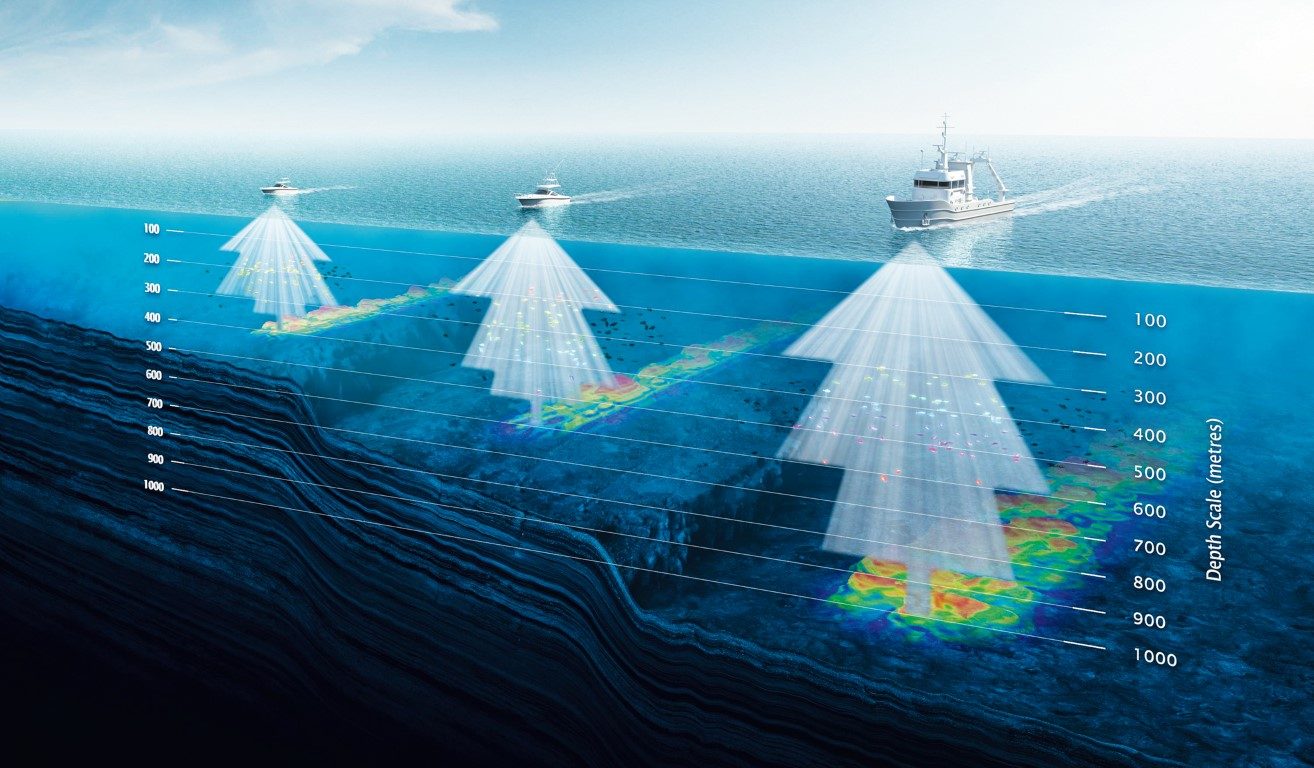

By 2000 ENL had developed a multi-beam echo sounder for commercial fishing.

“We saw a gap in the market for real-time mapping of the ocean floor and the water column. A technology that could serve not only commercial fishing, but also the hydrographic sector.

“Joining forces with the then Industry Research Ltd (now Callaghan Innovation) we developed a multi-band sonar system and called it WASSP – Wide-angle Seafloor Sonar Profiler. It comprises a transducer and software that captures a range of information – water column activity, bottom contours, bottom hardness – with its 120° sweep.

“It manages and interprets this information and presents it in exceptional 3D detail – in real time. Fishermen like the technology because it’s very easy to use and they don’t have to allow for the vessel’s pitch-and-roll.

“A major factor in its success was its ability to interface seamlessly with third party manufacturers of navigation technology. This was particularly important for the international hydrographic industry where six or seven different software suites are used.”

WASSP, he stresses, has become an increasingly important tool in a transformed commercial fishing sector.

“The sector wants to function more efficiently, accurately and sustainably – after all, its long-term viability is dependent on that. Catching the wrong species has a major impact on the fishing business. It also operates under stringent environmental parameters. WASSP is a valuable tool for meeting these objectives. In parts of Europe today the fleets will not go fishing without WASSP. It has very strong brand equity in the Scandinavian and Nordic countries.”

In an unexpected development, WASSP is also being used to locate ‘ghost nets’ – fishing nets which have broken free. Retrieving the nets not only mitigates financial losses, it also ensures they don’t become a threat to marine life or shipping traffic.

Today WASSP is well-established in more than 30 countries servicing markets that span numerous defence forces, the commercial fishing, hydrographic and superyacht sectors – as well as recreational boating. There are some 3,000 WASSP systems installed worldwide – with an average value of about US$45,000. Europe is the major market – for both the commercial fishing and hydrographic sectors.

“We established a UK branch recently,” say Hodson, “which might seem a little crazy in the Brexit/Covid context – but it’s been very successful. We also have a chap based in Italy, looking after the superyacht and expedition yacht fleets. This is a rapidly-expanding market for us – thanks largely to W3P, our new wireless WASSP product.

“These vessels often visit exotic spots in remote places. In charge of multi-million-dollar assets, their skippers like to have as much information about the bottom as possible before anchoring. In the W3P scenario, a WASSP module is mounted on a tender moving ahead of the mother ship. It relays the scanned information back to the skipper.”

Future

There’s no time to rest, says Hodson.

“Our strategy is clear. We will increase our R&D capability, introduce additive and robotic manufacturing, and continue to invest in markets across the planet.

“WASSP is wholly-manufactured in New Zealand. It has 2,000 components – including ceramics – and while we are currently a high-value-low-volume manufacturer, the growth in new markets will require a boost in output. Robotic manufacturing is an obvious strategy.”

Much of this thinking, he adds, has also been shaped by Covid. “Relying on external or contract manufacturing in a pandemic environment is risky. We could be very vulnerable – inhouse, lean manufacturing is safer.” ENL was ISO9001-accredited in 2006.

Japan’s Furuno is a 60% shareholder of ENL and one of the relationship’s major benefits, says Hodson, is being able to access the electronic giant’s R&D resources. “Furuno is also our distributor in 80% of the fishing markets around the world. Being able to tap into that distributor network – especially in North America and Southeast Asia – is crucial for our growth.

“Above all, though, our future is about nurturing our company culture and ensuring that we have a team that can react to changing market dynamics quickly and efficiently. We live in interesting times.”

Talent

ENL employs around 60 staff of which nearly two-thirds have engineering backgrounds. Among them are quite a few professors and PhD graduates.

“It’s important to acknowledge the depth of expertise within the ENL team,” say Hodson. “Observers might imagine our strategic direction is fixed solely by management. In fact, we have an awful lot of really clever software and hardware engineers.

I can honestly say the team drives our R&D and culture.

“This is a pool of people good at identifying opportunities and developing solutions to make them work. If management does have a focus, I’d say it’s about getting the right talent and nurturing it. The staff have grown ENL from a family business to a successful export business – not me.”

Real-time imaging

WASSP is fast – really fast. It has to be to be effective.

The multi-beam technology profiles the seabed 100 times faster than a single-beam echo sounder. This gives users a detailed, 3D, high-resolution image of what’s beneath the vessel.