How does a young Kiwi designer overcome the barriers hampering entry to the boatbuilding market? Offering something different is a good start. Words by Lawrence Schaffler.

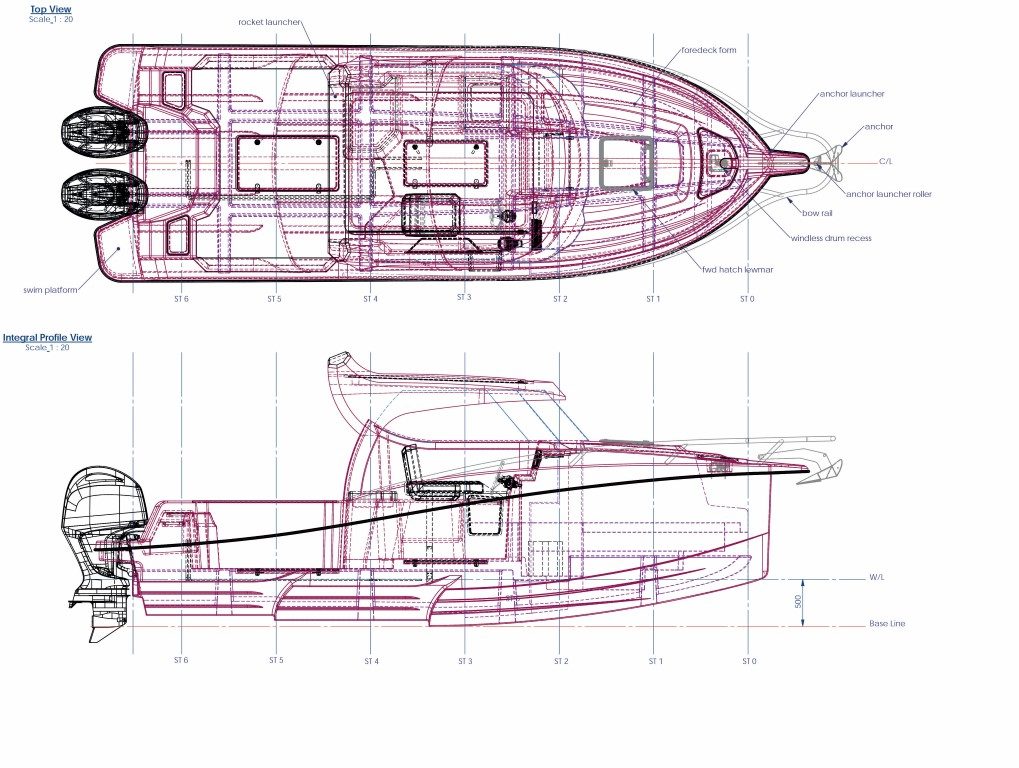

The BuiltBoats nu.seaera 24 Hard-top (LOA 7.50m) is a new concept design looking for an owner or investor willing to consider something that’s – well, a little unusual as 7.5m trailer boats go.

Distinguishing features are obvious. There’s the plumb bow, the large window in the hard-top roof, the spacious accommodation, the bathroom and toilet – all encompassed in clean-flowing lines and GRP construction.

But closer examination reveals far more intriguing features – a stepped hull and a built-in, electronically-driven stabiliser for when the boat’s at rest. These enhance speed, handling and fuel-efficiency, all while minimising any susceptibility the occupants might have to seasickness.

She’s the creation of Auckland design duo Matt Gibson and Andrew Copson who spent three years developing the 24HT. Between them there’s a substantial track record in boat design, and they’re keen to advance the stepped/ stabilised hull as a viable alternative to trailer boating in New Zealand.

Their company – BuiltBoats – is named that because they, er, want to build boats.

STEPPED HULL?

They’re relatively rare around New Zealand, Gibson concedes, but massively popular in the US.

“There are numerous advantages over conventional hulls. Major ones include a substantial reduction in hull drag, improved speed and fuel-efficiency. A stepped hull delivers clean water upwards to the props, which allows the engines to be set higher, further reducing drag.

“Once the hull’s on the plane, the steps provide lift, again reducing the wetted surface for greater efficiency and speed. In effect, you can run fast and cover a lot of water, saving money by going further, more quickly, with the same amount of fuel.

“Integrated speed rails and strakes enhance performance, helping the hull to track properly and remain stable during cornering. That’s coupled with an aggressive deadrise for piercing through chop, and flatter aft sections to promote optimal stability at rest.”

The hull design meets CE category B. Gibson is coy about the precise design of the stabiliser technology, but says it’s not intrusive and doesn’t take up excessive space in the vessel’s hull. It’s manufactured from off-the-shelf components.

The hull design meets CE category B. Gibson is coy about the precise design of the stabiliser technology, but says it’s not intrusive and doesn’t take up excessive space in the vessel’s hull. It’s manufactured from off-the-shelf components.

CONSTRUCTION

He is more expansive about the 24HT’s construction.

“It’s a composite structure – and a cost-effective design that provides ease of construction through ‘one-piece’ moulded parts, reducing the overall part count. Of course, it offers plenty of flexibility. If a customer wanted a lighter boat, we can build in carbon-fibre. Conversely, for more price-conscious customers, we can build from more cost-effective materials such as e-glass.”

Gibson also points out that up- or down-scaling the vessel’s size is simple.

“It’s a fully parametric design that uses advanced 3D modelling software. So if someone wants a vessel a metre longer or shorter, we can produce a complete 3D assembly in days. A re-development like that would typically take months.”

Exterior styling, he says, fuses an American sportsfisher’s look and feel with a modern, European interior design. The lightweight hardtop is equipped with a large sun roof, quickly opened for cool air to pass through the cabin. Inside, you’ll find a forward cabin with a spacious double berth and a head with shower and sink. Interior cushions are made from treated organic hemp – designed for longevity in a marine environment.

The combination of the plumb bow and transom extended all the way aft create maximum waterline length. This also makes for a generous aft deck. Twin 300hp outboards are easily accommodated on the transom, and inboard fuel bladders (situated mid-ships) hold 350-litres of fuel. The ISOTTA steering wheel has built-in push controls for controlling audio, trim and the stabiliser.

The vessel rides on a conventional trailer fitted with ‘track’ rollers – and is particularly compatible with the Balex trailer technology.

THE DESIGN TEAM

Matt Gibson – awarded a Bachelor of Design (Honours) in 2005 from Massey University, specialising in marine design and naval architecture.

The course included regular mentoring from design industry heavyweights, including some actively working in America’s Cup campaigns. Has done design work for companies such as Sealegs, Vaudrey Miller, Fulham Industries (Graham Hart’s Superyacht Development Team) and Yacht Werft Meyer (German superyacht tender manufacturer). Has also worked alongside internationally-renowned marine designers such as Phillipe Stark and Patrick Banfield.

Andrew Copson – completed a Bachelor of Technology, majoring in marine design. Has extensive practical boat experience after years of yachting experience, off shore sailing, commercial ship building and thousands of hours on the Hauraki Gulf.